Repairs to sheet metal airplanes fall into two categories: simple, which doesn't involve damage to structural members or affect the balance of control surfaces, and major, which encompasses repairs not covered by the simple category. They are not used in critical applications.One of the advantages of building your own airplane is that, if you build it, you can fix it. They have sawed or split bodies with sharp ends to make their own holes through leather, fiber, plastic, or soft metals. 43) are the standard “home repair” rivets. Split Rivets: Split (bifurcated) rivets (fig. Part of the sandwich material is not drilled, and the rivet pierces all the way or most of the way through while mushrooming out to a locked position. 42) are similar to semitubular rivets, except that they have greater column strength. Metal-Piercing Rivets: Metal piercing rivets (fig. It is a weaker rivet than the semitubular rivet, but it can pierce softer materials such as plastic or fabric. 41) has a deeper hole than the semitubular rivet.

Define rivet full#

40) has a hole in the field end (hole depth to 1.12 of shank diameter) such that the rivet approaches a solid rivet when the field head is formed.įull Tubular Rivets: The full tubular rivet (fig. Semitubular Rivets: The semitubular rivet (fig. These rivets are used commercially in soft materials and where a good appearance is required on both sides of the part. 39) consists of two parts that have an interference fit when driven together. Some specific types of tubular rivets areĬompression Tubular Rivets: A compression tubular rivet (fig. They are normally used for commercial applications rather than in the aerospace industry. Since extensive cold forming is required on these rivets, they must be extremely ductile and are consequently made of low strength materials.

The hollow end is cold formed to a field head. The generic form has a manufactured head on one side and a hollow end that sticks through the pieces being joined. Tubular Rivets: Tubular rivets are partially hollow and come in a variety of configurations. They are used primarily for commercial sheet metal applications. Although drive-pin rivets can be installed quickly, they are usually not used in aerospace applications. The head is normally hexagonal to prevent rotation of the tubular body while the mandrel is being torqued and broken off.ĭrive-Pin Rivets: This rivet has a drive pin that spreads the far side of the rivet to form a head, as shown in figure 38. 37(a)) has a threaded internal mandrel (stem) with the external portion machined flat on two sides for the tool to grip and rotate. Threaded-Stem Rivets: The threaded-stem rivet (fig. A generic pull-mandrel rivet is shown in figure 36. When the proper load is reached, the mandrel breaks at the notch. Pull-Mandrel Rivets: This rivet is installed with a tool that applies force to the rivet head while pulling a prenotched serrated mandrel through to expand the far side of the tubular rivet.

Define rivet install#

Less training is required for the operator.īlind rivets are classified according to the methods used to install them:.Clamping force is more uniform than with solid rivets.Installation time is faster than with solid rivets.A given-length rivet can be used for a range of material thicknesses.They can be used where only one side of the workpiece is accessible.

Define rivet portable#

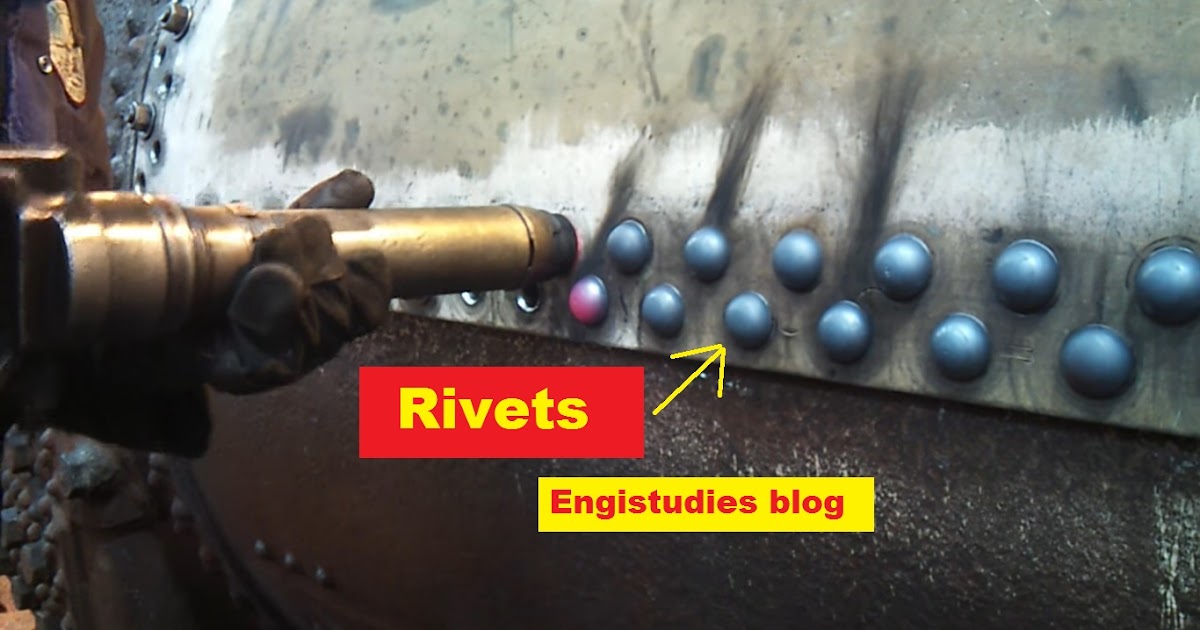

Thus, solid rivets must have cold-forming capability without cracking. Solid Rivets: Most solid rivets are made of aluminum so that the shop head can be cold formed by bucking it with a pneumatic hammer. From a structural design aspect the most important rivets are the solid and blind rivets. The general types of rivets are solid, blind, tubular, and metal piercing (including split rivets).

0 kommentar(er)

0 kommentar(er)