Scarcia, U., Berselli, G., Melchiorri, C., Ghinelli, M., & Palli, G. Bistable mechanisms for space applications. Zirbel, S., Tolman, K., Trease, B., & Howell, H. Bioinspired trimodal macro/micro/nano-porous scaffolds loading rhBMP-2 for complete regeneration of critical size bone defect.

Journal of Microelectromechanical Systems, 29(2), 214–227.

Engineering a compliant mechanical amplifier for MEMS sensor applications. Design and analyze of flexure hinges based on triply periodic minimal surface lattice. International Journal of Precision Engineering and Manufacturing, 19, 109–118.Ījpa, B., Bjwa, B., Cyza, B., et al. Design and testing of a new 3-DOF spatial flexure parallel micropositioning stage. Journal of Bionic Engineering, 14(1), 1–14. The merits of passive compliant joints in legged locomotion: Fast learning, superior energy efficiency and versatile sensing in a quadruped robot. International Journal of Precision Engineering and Manufacturing, 21(3), 483–490. A novel parallel precision stage with large working range based on structural parameters of flexible hinges. Journal of Mechanical Engineering, 46(13), 2–13.

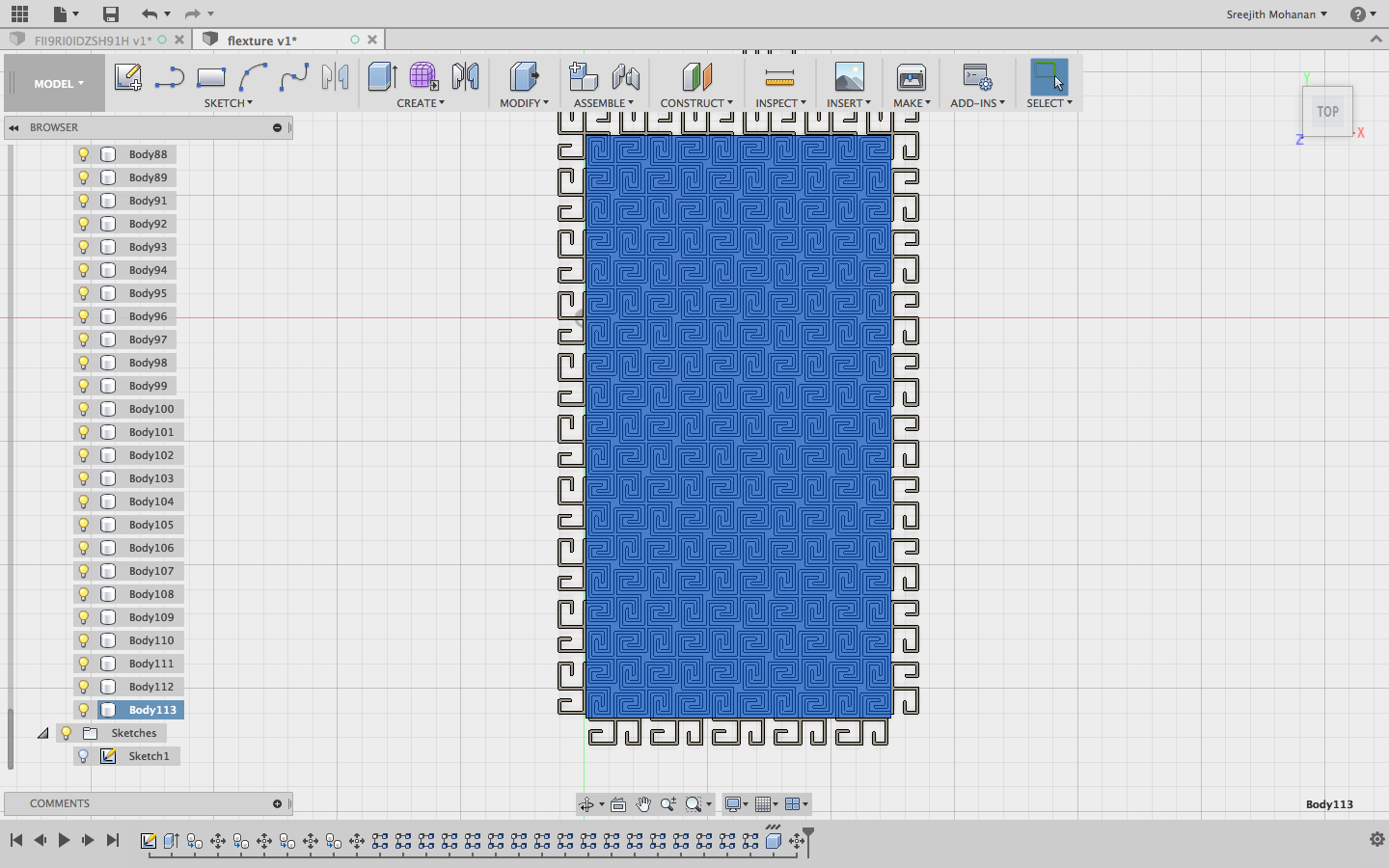

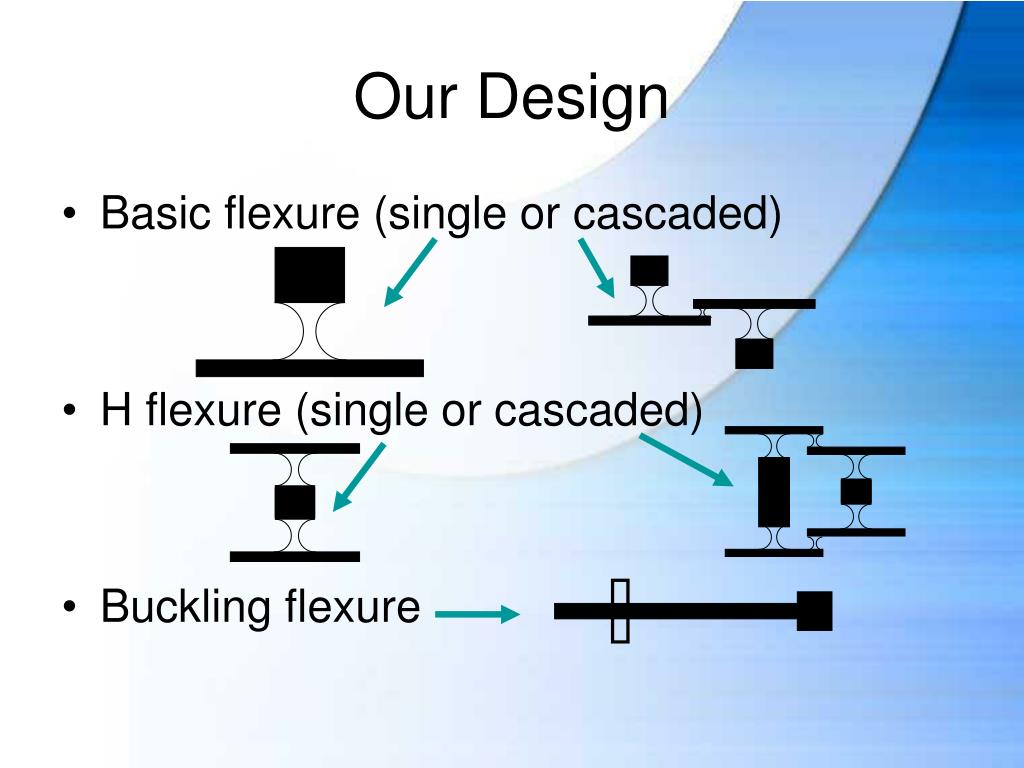

State-of-arts of design method for flexure mechanisms. Compared with the traditional flexure hinge, the developed design demonstrates a higher range and accuracy of rotation and a better ability to preserve the rotation center position but smaller compliance, which demonstrates a significant potential for emerging applications, including optical adjustments, biomedical operations, and robot joints. The characteristics of the flexure hinge were further verified by finite element simulations and experiments on an additive manufactured prototype. The stiffness model of the flexure hinge was derived based on the elastic beam theory to illustrate the load–deflection relationships. Owing to the excellent deformation capability and geometric constraints of the spatial spiral structure, the developed flexure hinge is capable of deflecting up to 90° with a small axis drift. In particular, the ∞-shaped configuration was adopted along the width direction of the flexure hinge by adjusting the spiral diameters. By overcoming the limitations of traditional manufacturing technologies, this study develops a novel spatial spiral-based flexure hinge that aims to have a large stroke and high accuracy. This book aims to provide scientists and engineers with a conceptual tool, an analytic methodology and the key references for their precision engineering needs.Additive manufacturing technology has significant potential for the development of advanced compliant mechanisms for precision manipulations owing to the advantage of realizing complex monolithic structures. The book also features detailed examples of long stroke flexure mechanisms used in metrology applications, and a detailed example of planar flexure mechanisms having out of plane functionality and used in surgical applications.

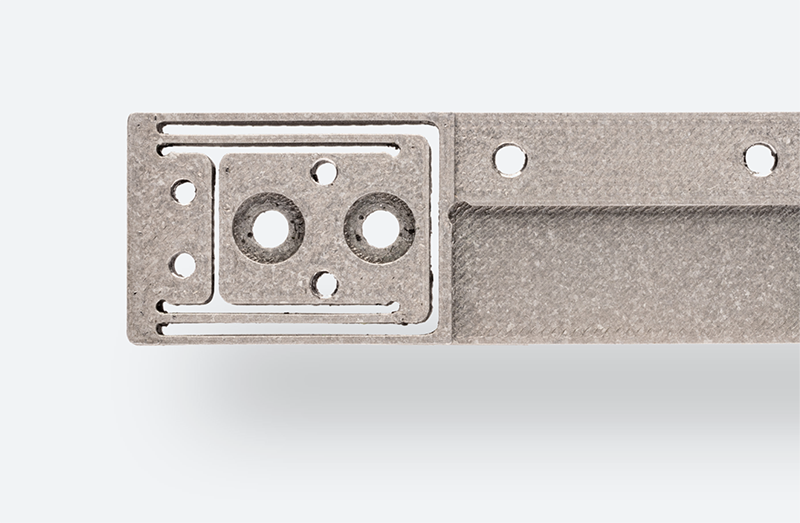

Flexture design serial#

Topics featured deal with the theoretical foundations for the design of translational and rotational flexures, the simple kinematic analysis of flexure-based mechanisms, and advanced kinematic approaches to the design of complex flexure-based mechanisms using modules in parallel or serial arrangements. This book establishes a conceptual framework for the design of flexure-based articulated structures. Flexure-based mechanisms have gained prominence in a wide variety of fields including robotics, surgical instrumentation, aerospace, astronomy, particle accelerators, metrology and horology. Flexure mechanisms eliminate the disadvantages of classical joints: friction, wear, lubrication and play, while permitting monolithic design. Flexure mechanisms, also known as compliant mechanisms, rely on the elasticity of matter to provide motion to mechanism linkages. Flexure mechanism design is an art, and this book provides the theoretical and practical foundation for scientists and engineers to express their creativity in this field.

0 kommentar(er)

0 kommentar(er)